Nowadays, to be able to optimize the project and forecast the product’s behaviour before starting the production is a fundamental competence in order to keep up with an increasingly evolving market.

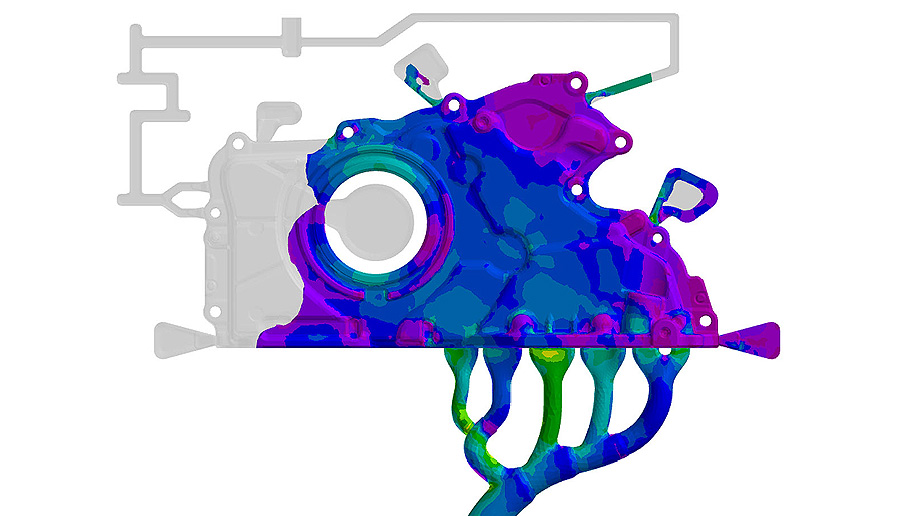

Thanks to the software ProCast we are able to virtually produce the parts, measuring and analysing their quality and the performance. Through the filling simulation software, it is possible to observe how the aluminium will flow inside the mold. We enter data such as speed and temperature and we can create the right injection gate to obtain a piece free of porosities and defects.

If, indeed, the virtual quality control does not satisfy the conformity of the part, we intervene immediately with the computer by modifying the tool and the process parameters in order to adjust possible problems. This procedure is done until we reach the requirements of the Supply Specifications.

Not only the filling simulation software brings to an improvement from the point of view of the design of the mould, but it allows to contain costs as well, by making virtual samplings to reduce them.